7:30 AM - 6:00 PM MON - FRI After Hours Contact Lee Osborne

-

-

606 Wardell Ind. Park Rd. Cedar Bluff, VA 24609

7:30 AM - 6:00 PM MON - FRI After Hours Contact Lee Osborne

606 Wardell Ind. Park Rd. Cedar Bluff, VA 24609

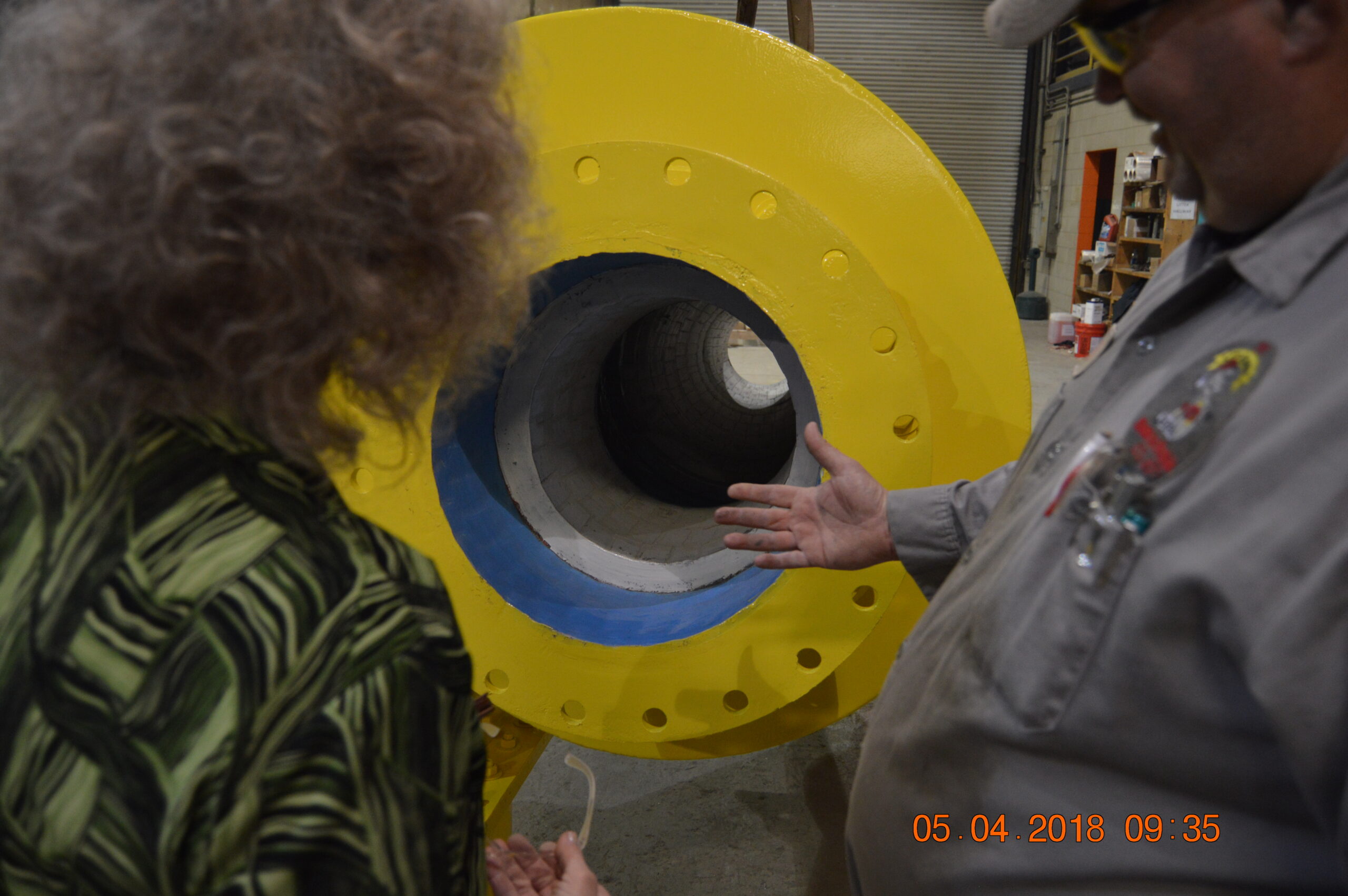

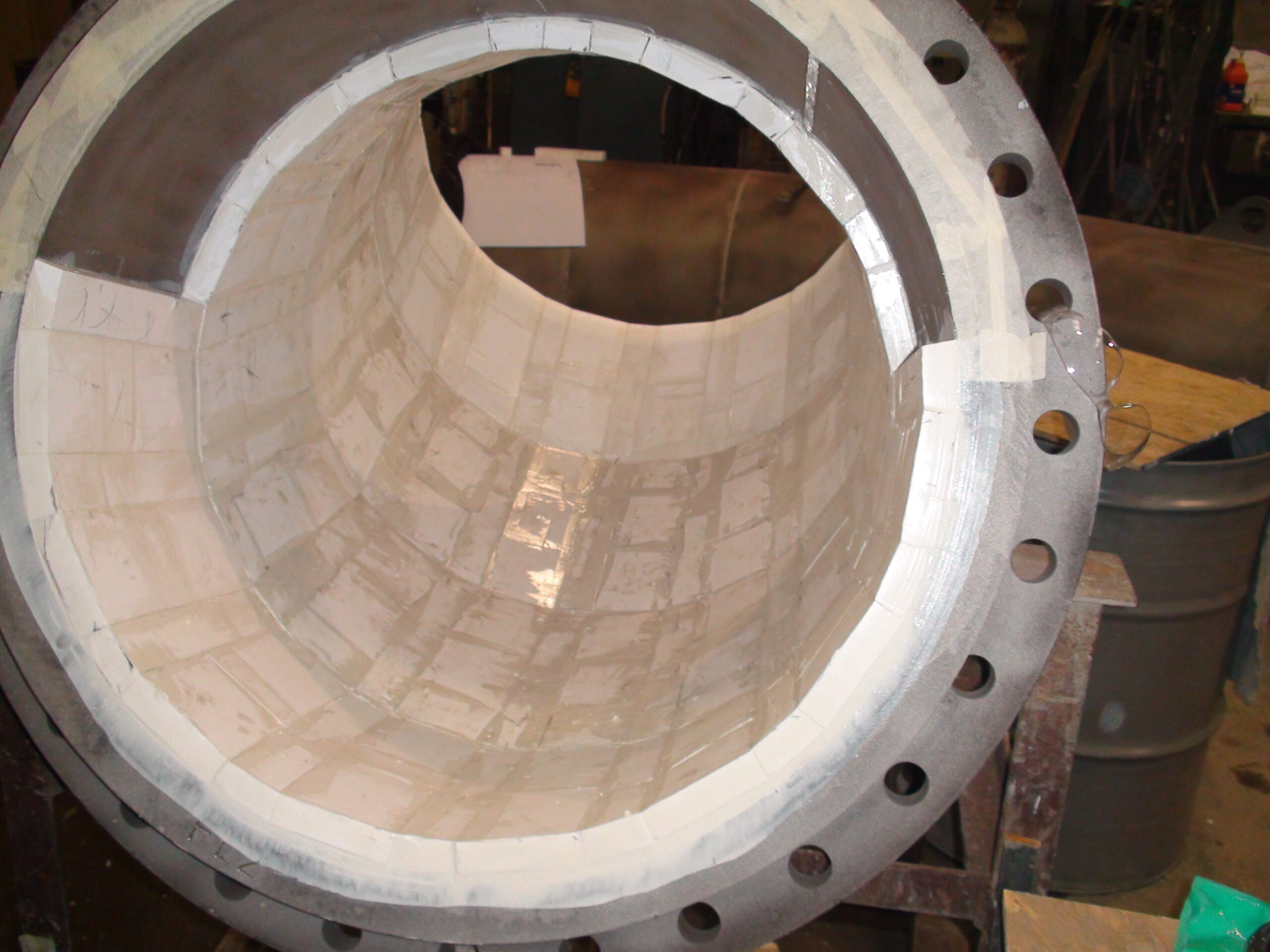

As urethane and rubber liner costs continue to rise, our ceramic pipe lining services offer a smarter, longer-lasting alternative for 24"–40" pipe systems. Ceramic liners deliver 4–5x better cost performance while dramatically outperforming traditional materials in extreme wear environments. High-impact elbows and fittings—where velocity and abrasion are most destructive—are strategically reinforced with ½" and 1" ceramic tile configurations at critical impact points.

This targeted approach doesn’t just slow wear; it extends piping life by 10–15 times, reducing downtime, replacement frequency, and long-term operating costs. The result is a purpose-engineered lining solution designed for real-world industrial abuse—built to last, perform, and pay for itself over time.

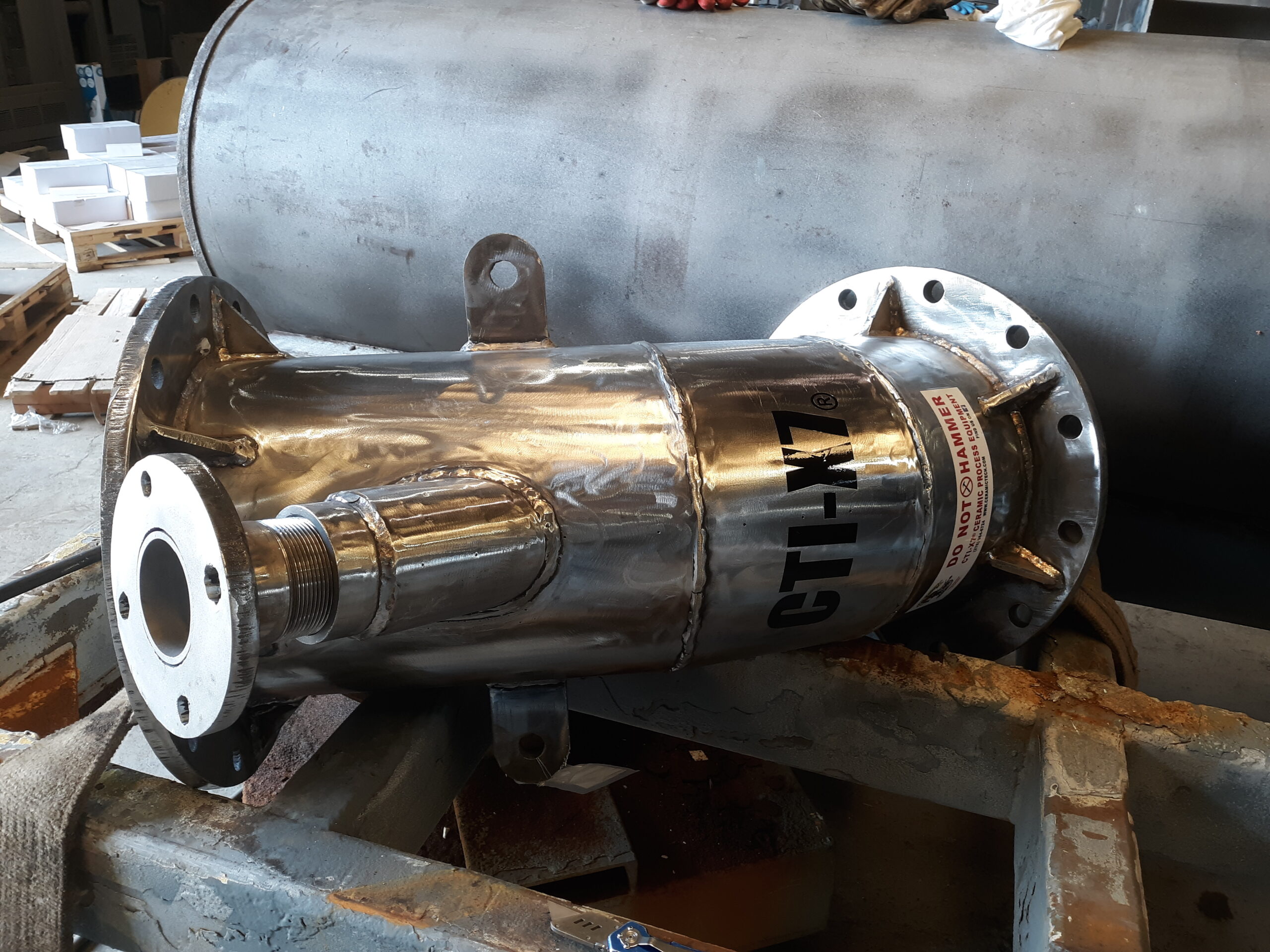

We design piping systems to integrate flawlessly with your existing infrastructure. Carbon steel piping (¼"–⅜" wall) is commonly used, with transition sections ensuring precise ID matching across straight runs. When required, 304 and stainless steel alloys are also available. Fabrication options include straight spools, elbows, and custom headers, all built to code with exact flange specifications. Every component is inspected, clearly marked, and installation-ready before leaving our warehouse—so your team spends less time adjusting and more time getting up and running.

Every component undergoes rigorous inspection and verification, ensuring consistent performance, compliance, and long-term reliability before it reaches your site.

Pre-engineered assemblies and precise fit-up reduce field modifications, accelerate installation timelines, and get your operation running efficiently with minimal disruption.

CTI-X7® ceramic pipe systems are purpose-built to perform where conventional piping fails. Designed to meet extreme operational and environmental standards, each system combines advanced ceramic liners with carbon steel or stainless steel housings. The result is exceptional resistance to abrasion, corrosion, and thermal stress. Whether handling high-velocity flow or aggressive materials, CTI-X7® delivers consistent, long-term performance in the harshest industrial conditions.

CTI IMPACT ELBOWS

CTI-X7® equipment delivers rapid ROI by dramatically extending service life and reducing downtime. In many applications, ceramic-lined systems outperform schedule 40 and 80 unlined pipe by up to a 20:1 ratio. Fewer replacements, fewer shutdowns, and lower maintenance demands translate directly into measurable cost savings. Plants gain improved throughput and reliability while protecting capital budgets from recurring piping failures.

Accuracy starts before fabrication. CTI-X7® engineers use rapid 3D modeling to define exact dimensions, tolerances, and flow dynamics. Designs are reviewed collaboratively with plant managers to ensure seamless integration into existing systems. This precision-driven approach minimizes field modifications, shortens installation time, and supports just-in-time delivery—keeping projects on schedule while maintaining exceptional build quality and operational confidence.

CTI IMPACT ELBOWS

High-volume, high-velocity flow is managed through engineered impact sections designed to dissipate energy safely. CTI-X7® systems reduce localized wear while smoothly transitioning between different pipe schedules. These design features protect downstream components, stabilize flow patterns, and extend system life. The result is predictable performance even in demanding transfer points where erosion and turbulence typically cause premature failures.

Ceramic-lined carbon steel or stainless steel pipe virtually eliminates spill risk. The liner forms a continuous, wear-resistant barrier that prevents breaches caused by abrasion or corrosion. This design protects surrounding equipment, personnel, and the environment. By reducing leak potential at its source, CTI-X7® systems help facilities maintain cleaner operations while avoiding costly cleanup, liability exposure, and unplanned shutdowns.

CTI IMPACT ELBOWS

CTI-X7® systems are engineered to reduce total lifecycle effort. Longer service intervals mean fewer inspections, repairs, and replacements. Modular designs and precision fabrication simplify installation, lowering labor costs and minimizing disruption to operations. Maintenance teams spend less time reacting to failures and more time focusing on optimization—improving overall plant efficiency while reducing long-term operating expenses.

By preventing leaks and premature blowouts, CTI-X7® helps facilities stay compliant and inspection-ready. Clean operations reduce scrutiny from state and federal inspectors while lowering the risk of citations or fines. The durability of ceramic-lined pipe supports consistent performance under pressure, giving plant operators confidence that their systems will hold up under both operational demands and regulatory oversight.

CTI IMPACT ELBOWS

Unlike rubber-lined pipe, CTI-X7® ceramic systems eliminate fire hazards that require specialized handling or unique safety setups. The non-combustible ceramic liner supports safer operation in high-temperature or high-risk environments. This improves overall plant safety while simplifying compliance and reducing insurance concerns. The result is a more efficient, secure operation designed with both performance and people in mind.