7:30 AM - 6:00 PM MON - FRI After Hours Contact Lee Osborne

-

-

606 Wardell Ind. Park Rd. Cedar Bluff, VA 24609

7:30 AM - 6:00 PM MON - FRI After Hours Contact Lee Osborne

606 Wardell Ind. Park Rd. Cedar Bluff, VA 24609

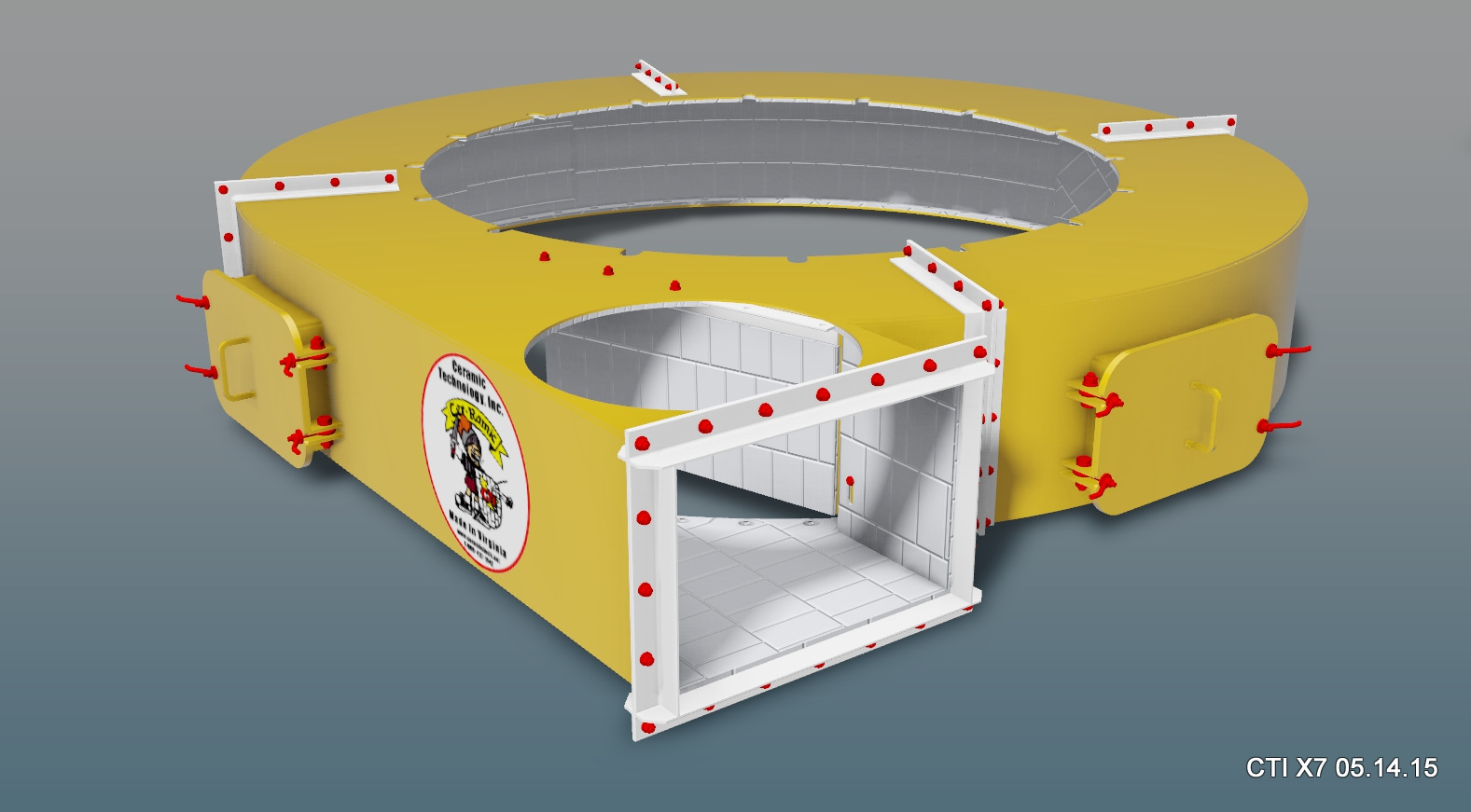

CTI-X7® delivers a disciplined, engineering-led ceramic lining specification that turns maintenance from reactive to strategic. As a Class-A Contract Manufacturer, we partner with plant teams to redesign failure-prone components, upgrade circuits, and support expansions without disrupting throughput. Our engineers collaborate directly with Reliability and Maintenance leaders, aligning ceramic solutions to real operating conditions, not generic assumptions.

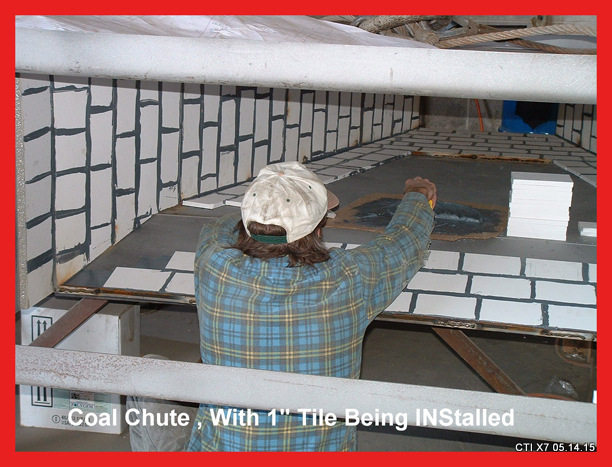

By applying the X-7® Ceramic Standard across piping, chutes, cyclones, and distribution systems, plants routinely replace rubber, AR, and chromium carbide liners with longer-lasting ceramic systems. The result is measurable gains in uptime, safer operations, and optimized material flow, all driven by a clear specification that standardizes performance, simplifies maintenance planning, and accelerates return on investment across demanding industrial material processing environments nationwide today.

In high-risk environments, CTI-X7® ceramic-lined systems deliver critical safety and resilience advantages. During emergency blowouts, carbon or stainless steel with ceramic can be temporarily welded, minimizing environmental spills and unplanned shutdowns. Unlike rubber-lined systems, which introduce fire hazards during hot work, ceramic solutions maintain structural integrity under repair conditions. This flexibility protects people, equipment, and production continuity, while buying operators valuable time to plan permanent repairs without catastrophic operational failure.

CTI-X7® ceramic systems reduce fire risks, protect personnel, and maintain integrity, keeping high-risk operations safer and more controlled.

Temporary repairs with ceramic-lined components prevent unplanned shutdowns, preserving production continuity and reducing costly emergency maintenance.

The CTI-X7® Ceramic Performance Standard has gained worldwide recognition for reliability in material processing. Detour Gold’s Reliability Team highlighted that impact abrasion and premature wear on their 30" ball mill lines were hurting production due to repeated pipe and fitting failures. CTI-X7® addresses these issues with innovative design, extending equipment life, minimizing downtime, and boosting plant efficiency—making it a trusted solution for mining operations facing extreme wear and tear challenges.

CTI IMPACT ELBOWS

Premature wear in material processing equipment often triggers unscheduled maintenance, disrupting production schedules. CTI-X7® Impact Elbows have been engineered to withstand these conditions, processing 55,000 tons of material per day and displacing traditional steel grinding balls. By extending elbow life to 10 months and handling over 17 million tons of gold ore, CTI-X7® reduces maintenance interruptions, allowing plants to achieve up to 30% higher throughput and significantly lower operational stress.

Detour Gold’s Reliability Team recently scored first place in an international competition, competing against industry giants like DOW-Aramco and Bayer Science. Their success underscores the importance of CTI-X7® equipment in maintaining uninterrupted operations. The performance of these ceramic components demonstrates that cutting-edge design and material engineering can outperform traditional solutions, giving mineral processing operations a decisive advantage in both productivity and cost management.

CTI IMPACT ELBOWS

The CTI-X7® trademarked performance standard, federally registered in 2014, has become synonymous with operational efficiency. Using the X7® brand minimizes costly plug-ups, blow-outs, and unscheduled downtime. Plants see a measurable return on investment—often 20–25%—through fewer repair cycles, reduced accident risks, and lower labor costs. By preventing environmental spills and fines, CTI-X7® protects not only productivity but also regulatory compliance, making it a smart choice for modern mineral operations.

CTI-X7® Impact Plates and process equipment are engineered to handle high-impact abrasion and reactive acids, including 35% phosphoric and sulfuric acids. Strict application procedures ensure optimal performance, while heavy media cyclones and static screens improve classification and recovery efficiency. These components consistently deliver top performance, minimize material loss, and extend the life of screen panels, giving plants a competitive edge in throughput, safety, and equipment longevity.

CTI IMPACT ELBOWS

Beyond durability, CTI-X7® equipment significantly reduces noise amplification from coal and mineral handling. Noise control is a growing regulatory concern, with MSHA monitoring operational and personal exposure limits. Ceramic liners not only outperform steel in wear resistance but also contribute to safer, quieter work environments. Reduced noise levels protect personnel, improve productivity, and align with industry best practices, reinforcing CTI’s commitment to responsible, forward-thinking process equipment solutions.

Since 1985, CTI’s team of Reliability Engineers, Certified Welders, and Tile Technicians has built a respected brand in material process equipment. With operations spanning the U.S. and Canada, the CTI-X7® line supports coal, mineral, and gold mining operations with proven efficiency. The company’s commitment to high-quality manufacturing and service ensures consistent plant performance, helping customers maximize throughput, minimize downtime, and achieve a 25:1 ROI on equipment investments.

CTI IMPACT ELBOWS

CTI-X7® equipment installation is carefully managed from initial quote to final delivery. Customers receive pre-engineered layouts, G.A. drawings, and field-verified specifications, ensuring precise fit and operation. Liners are cut, welded, and finished to exact tolerances, typically delivered within 4–6 weeks, with expedited options available. This seamless process bridges the gap between cost-effective solutions and high-performance ceramic technology, supporting operational excellence across North American mineral processing plants.